This topic is not going to suggest that we do away with the internal (infernal) combustion engine, [ICE]. We have invested far too much in that development to abandon that work. I look here at the alternative designs and therefore possible changes to the design of the ICE

Just so you know what I’ve included here: the Wankel, the OPOC, the Sucederi, the Selzer, the free piston and its related electric motor.

The Otto cycle describes the spark ignition piston engine. Combustion engines include continuous combustion such as in gas turbines, jet engines and rocket engines. I look here at some of the variations that have been tried. I recommend a look at animated engines.

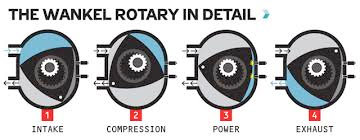

The Wankel Engine

Please see an animation

here. The Otto cycle is preserved but the pistons are combined with clever geometry to provide circular motion. This is a powerful engine once the seal technology is good (where the piston meets the chamber wall gets very hot so ceramic rotor tips are likely). It is a small motor, it works at high speeds and it is very smooth. My RX-8 was 1.3 but rated at 2.6 litres, putting out 230 bhp and revving very freely to 7000, with the usual engine note much higher than one is accustomed to with four-stroke engines. The RX-8 was discontinued because the new Euro 5 emission regulations. I averaged 29mpg across the years I owned the car, far better than advertised; even so, this is unacceptable fuel economy this decade. I continue to hope for a return.

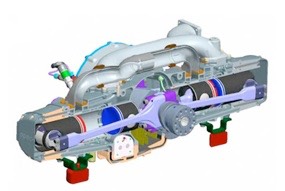

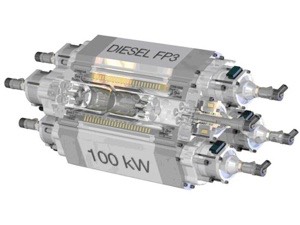

Opposed piston opposed cylinder [OPOC] as seen by EcoMotors is another variation on the ICE, but here (they’re not flat engines like the boxer and they’re not Selzer engines, next) they can have 1-3 cra

nkshafts. The diagram shows a single unit on such a shaft. Each cylinder has a piston at both ends; no cylinder head, no valves, so simpler and cheaper. As of 2013 EcoMotor have a deal with ZhongDing Power to build car engines, with the blocks made of compacted graphite-iron [CGI]; production may occur in 2015.

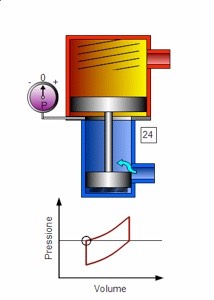

The Scuderi engine is an improvement on the usual ICE, with paired cylinders in a split cycle arrangement that aims to reduce or eliminate losses from re-compressing the gas. Where standard Otto cy

cle pistons fires every second stroke, Scuderi engines fire every revolution. If combined in an air hybrid, recovered braking energy would be stored as compressed air. March 2015 has lawsuits from Toyota slowing things down. See link at top of paragraph. I’m betting the Sucderi family are hoping to make money off the patents while richer people do the development.

The Stelzer engine has the pistons joined end-to-end. This simplifies manufacture and has fewer moving parts. Its long axis could be horizontal, offering weight low down in a flat cuboid, or vertical, giving a narrow vertical block.

Do not, as I did, misread Stelzer as Selzer, which leads you to Cox model engines. the Stelzer engine uses maybe 30% less gasoline and is cheaper to make, says the

NewYorkTimes1983. It would cycle about twice as fast as we are used to, at high rpm. I read that this engine would be excellent for a compressor because of the reciprocal motion. Quoting NYT and thence Opel:

''Its thermal efficiency is good, its mechanical efficiency is better than in conventional gasoline or diesel motors, and its durability is virtually unlimited.''

The biggest problem, he [the man from Opel] said, was to transform the engine's shuttle-like motion into the mechanical drive a car needs. Opel developed theoretical models, without using the engine, involving mechanical, electrical and hydraulic systems, he said. But none proved feasible because of excessive weight, cost or installation space.

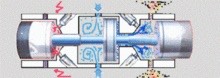

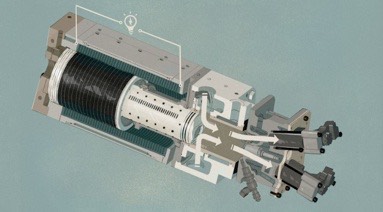

The Stelzer may be a Free Piston engine by being crankless

(yellow/blue picture from heatenginescienceblogspot.com).

The pistons lie back-to back in opposing pairs (an opposed piston CE) using a two stroke cycle. The combustion chamber lies between the pistons and the two outer chambers act as closed, providing rebound. So there is no crankshaft. These engines have been developed for compressors and gas generators - they work well if driving a turbine. the design is simple, so the engine is compact and has low maintenance.

Toyota has a prototype, whicj leads directly into the next page. In the FPEG (the link gives you a video), the piston goes through windings and produces 3-phase electricity - “The FPEG operates like a two-stroke engine but adds direct gasoline injection and electrically operated valves. It can also be run like a diesel, using compression rather than a spark plug to ignite its fuel mixture.” The comment included: a two-cylinder FPEG is inherently balanced and would measure roughly 8 inches around and 2 feet long. An engine of that

size and type could generate 15 hp, enough to move a compact electric vehicle at highway speed after its main drive battery has been depleted. That's the future.

Indeed.

See also the FKLG.

These developments of the internal combustion engine have the great advantages of developing what we already know a great deal about. The work done in developing the ICE to its current level works against the development cost of other designs - there is too much climbing to do. However, as fuels become more expensive (and more scarce), that work becomes worthwhile.

DJS 20150316

Did you miss a π moment? March 14th, ’15, at 9:26:53.. [3.14159265358979 to 15 s.f.]

If you come across some engine types I’ve missed, do share, please. Email button below somewhere.

3 In Mazda's RX-8 with the Renesis engine, fuel economy met California State requirements, including California's low emissions vehicle (LEV) standards. This was achieved by a number of innovations. The exhaust ports, which in earlier Mazda rotaries were located in the rotor housings, were moved to the sides of the combustion chamber. This solved the problem of the earlier ash buildup in the engine, and thermal distortion problems of side intake and exhaust ports. A scraper seal was added in the rotor sides, and by use of some ceramic-made parts in the engine. This approach allowed Mazda to eliminate overlap between intake and exhaust port openings, while simultaneously increasing the exhaust port area. The side port trapped the unburned fuel in the chamber, decreased the oil consumption, and improved the combustion stability in the low-speed and light load range. The HC emissions from the side exhaust port Wankel engine are 35–50% less than those from the peripheral exhaust port Wankel engine, because of near zero intake and exhaust port opening overlap. Although peripheral ported RCEs have a better mean effective pressure, especially at high rpm and with a rectangular shaped intake port (SAE paper 288A).[44][45] However, the RX-8 was not improved to meet EuroV emission regulations and was discontinued in 2012.[46] wikipedia/wankel

http://www.popularmechanics.com/cars/g195/5-alternative-engine-architectures/

https://www.masterresource.org/smil-vaclav/smil-density-definitions-i/

http://en.wikipedia.org/wiki/Power_density

http://en.wikipedia.org/wiki/Internal_combustion_engine

http://en.wikipedia.org/wiki/Thomas_Newcomen

http://www.animatedengines.com/ltdstirling.html

http://www.slashgear.com/precer-groups-bioracer-uses-wood-pellets-for-fuel-12107602/

http://en.wikipedia.org/wiki/Free-piston_engine

http://www.nytimes.com/1983/06/27/business/free-piston-engine-debated.html

http://www.digitaltrends.com/features/road-rave-free-piston-engines-power-next-plug-hybrid/